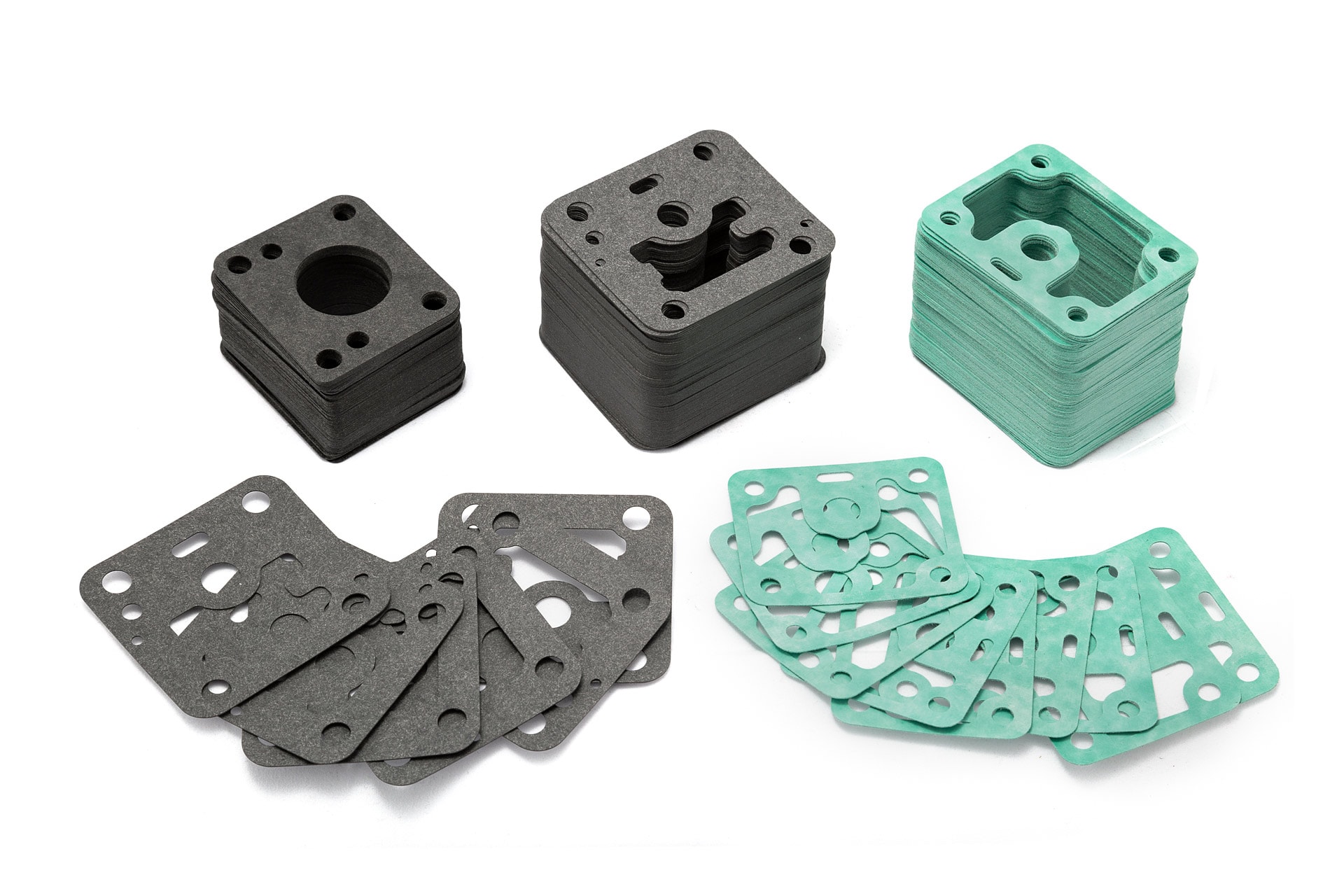

Gaskets for compressors

Gaskets are of vital importance for the proper operation of hermetic compressors, that constitute the vast majority of those used in both commercial and domestic refrigerators. It is a technology in use for decades, preferred for the high reliability required by compressors that must operate non-stop for years.

Most models use three types of gaskets: muffler, cylinder head and valve plate.

Most models use three types of gaskets: muffler, cylinder head and valve plate.

Noiseless and energy saving are primary objectives when designing compressors for refrigerators, and in this sense the valve plate gasket is particularly critical as it serves to compensate the space between the valve plate, which regulates the flow of refrigerant gas in the circuit, and the cylinder that provides the thrust. Too thin and the vibration at the head causes an excess of noise, too thick and the sliding area of the piston is reduced, limiting efficiency.

Compressor gaskets are made from special cellulose-based materials and manufacturers are subject to stringent regulations. In particular, for valve plategaskets technological evolution has reduced the tolerances in the order of a few microns on materials that, to carry out their function, are compressible and resilient.

Mecondor, thanks to its long experience in the sector, has created an unsurpassed ability in selection, that means that the most demanding customers' needs can be met. The creation and use of machines that match high precision with extreme selection speeds (up to 40,000 pieces/hour) has allowed us to gain a significant market share in this business around the world (tens of millions of pieces per year).

Mecondor, thanks to its long experience in the sector, has created an unsurpassed ability in selection, that means that the most demanding customers' needs can be met. The creation and use of machines that match high precision with extreme selection speeds (up to 40,000 pieces/hour) has allowed us to gain a significant market share in this business around the world (tens of millions of pieces per year).

Contact us >